How to choose a high flow filter supplier?

- date:

- browse:1

- 42.228.139.250-50018

How to choose a high flow filter supplier?

1. Size & Drawing:

According to the design drawings of PALL, Parker, 3M original filter element dimensions and the filtration performance of the original filter element, the filter material is reasonably selected.

1)Size

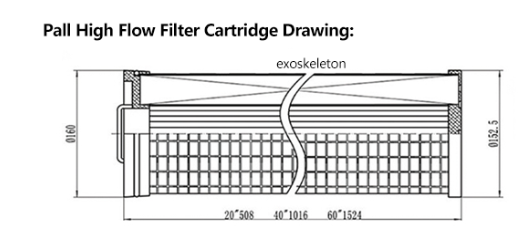

PALL high flow filter Size:

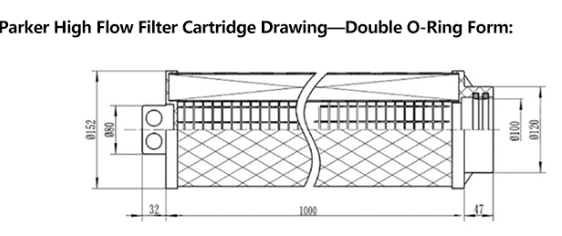

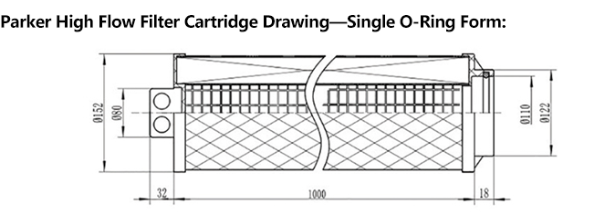

Parker high flow filter size:

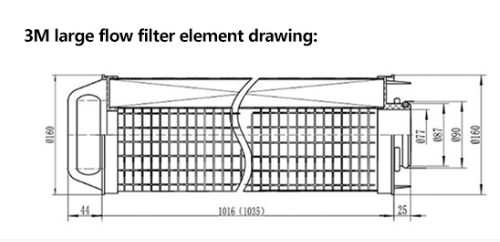

3M high flow filter Size:

2)high flow filter Filter material: PP membrane, fiberglass

PP membrane

It is made of polypropylene microfibers hot-melted and bonded together. It is a kind of membrane material for deep filtration. It has the following characteristics:

Using food grade isotactic polypropylene as raw material, no additives in the whole production process; stable physical and chemical functions, good compatibility; with a series of pore sizes, high porosity, large dirt holding capacity, recoil and high temperature Disinfection; good pressure resistance.

fiberglass

The composite glass fiber membrane is a traditional ultra-fine glass fiber membrane with polypropylene fiber membrane on both sides, which retains the high porosity of the ultra-fine glass fiber membrane, with large flux, large interception flow, and good temperature and corrosion resistance. It has the advantages of low strength, easy damage under pressure and falling off. It is a new type of filter element with excellent performance and wide application.

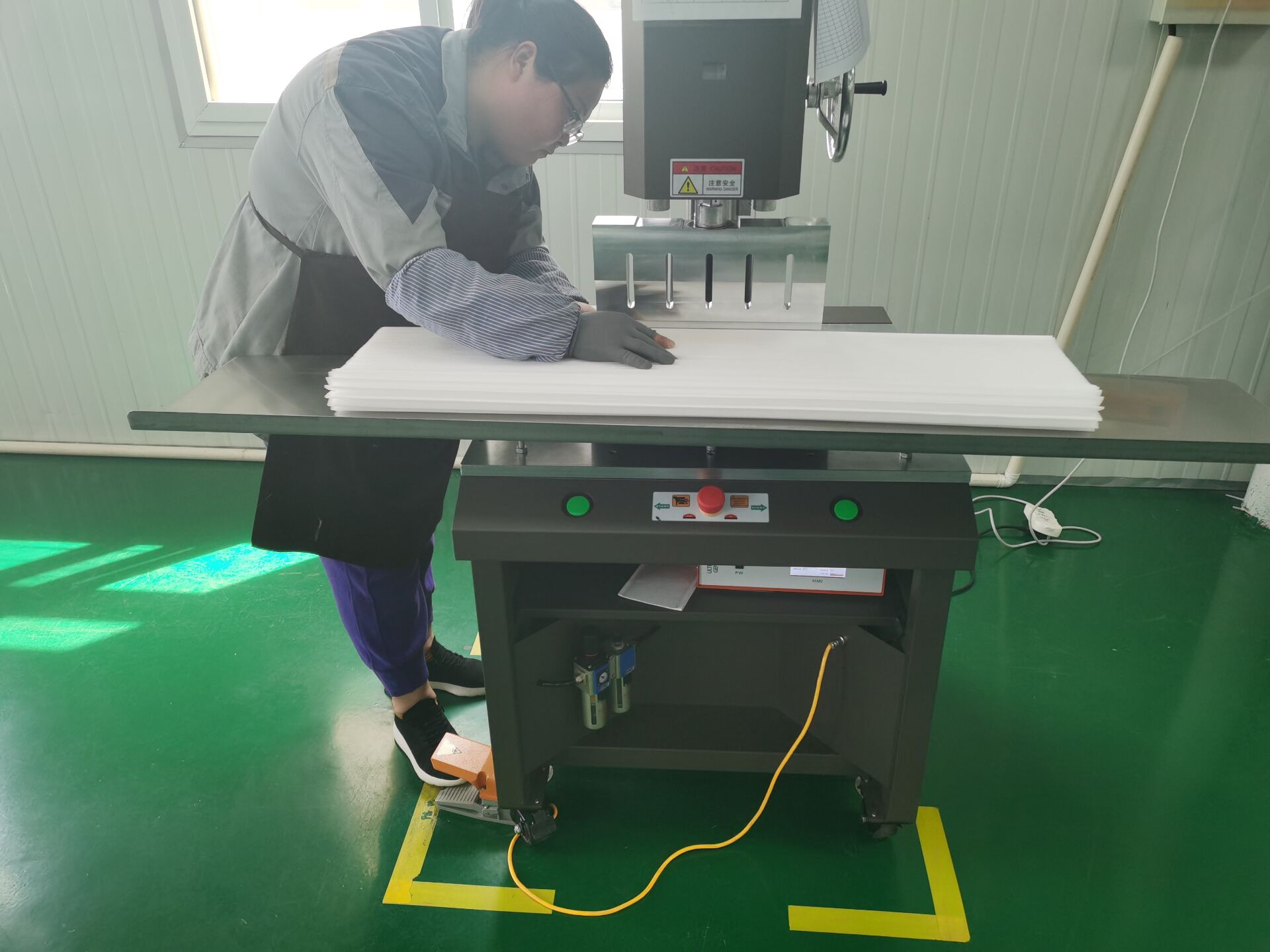

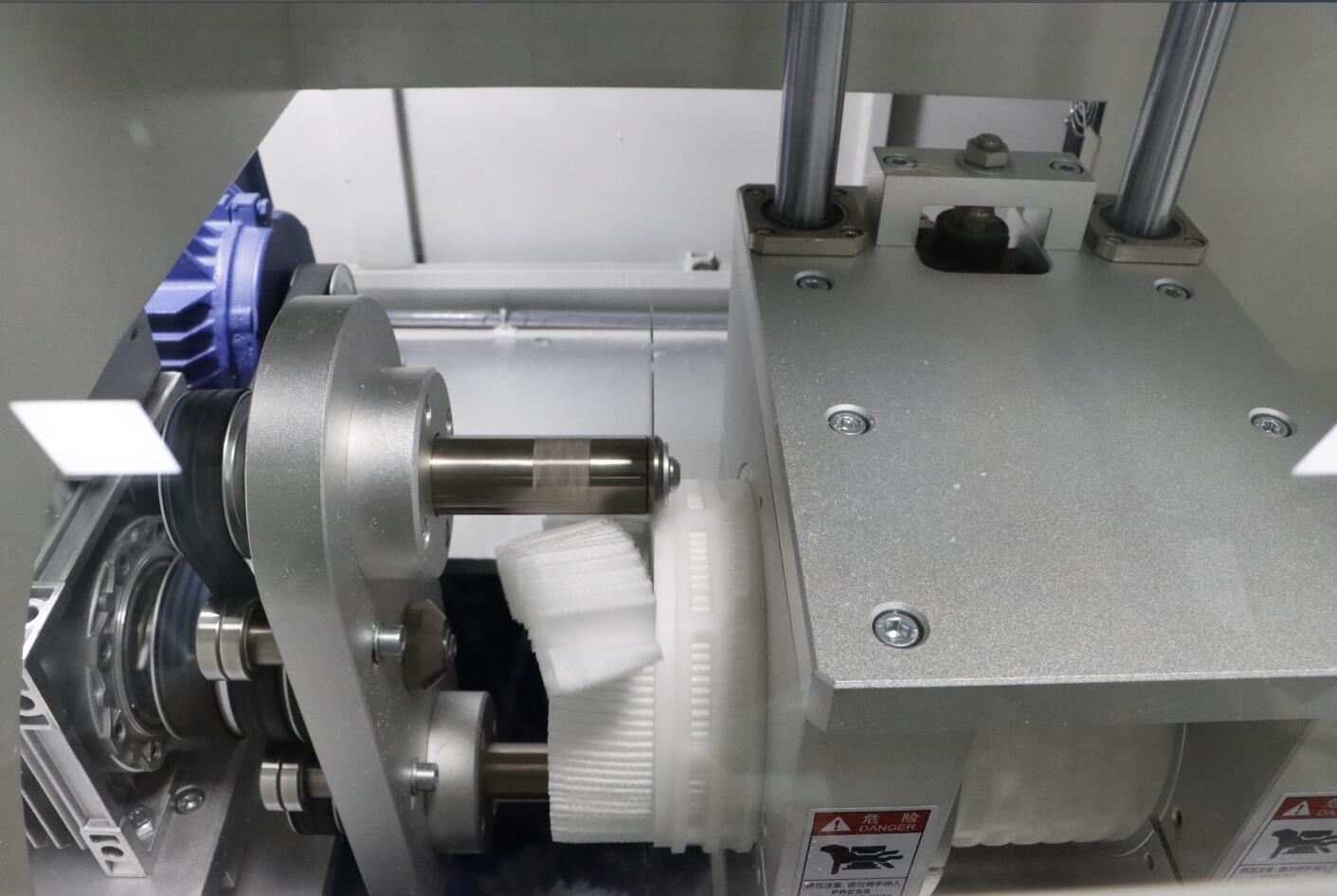

2.Whether there are relevant equipment and instruments for high flow filter manufacturing and inspection.

Production equipment

Test equipment:

3. Is the hygiene condition of the high flow filter production workshop kept clean?

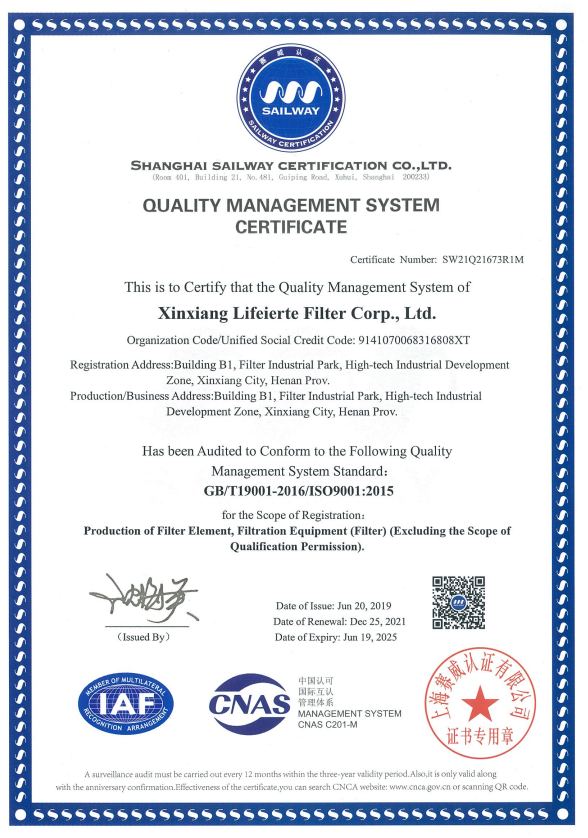

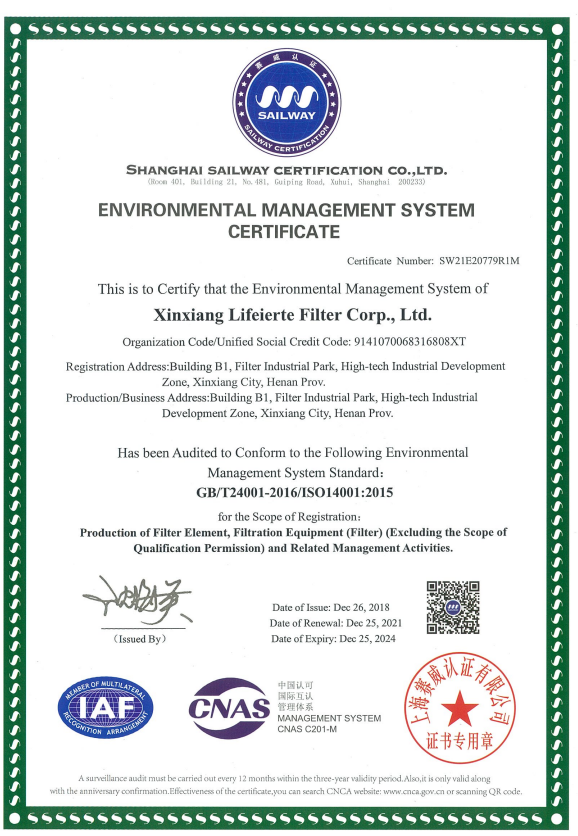

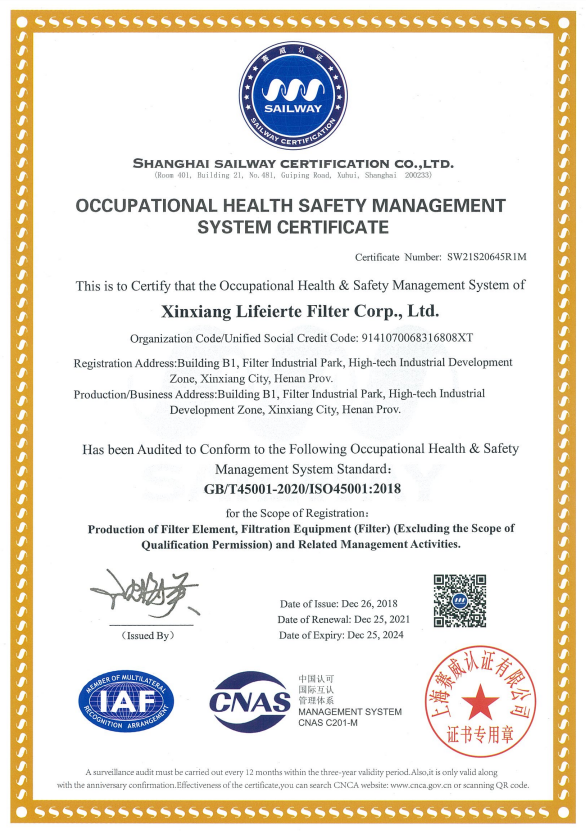

Company have got many certifications:

1) Quality Management System Certification

2)Environmental Management System Certification

3)Occupational Health Safety Management System Certificate

4. What is the production process of High flow filter ?

Please view production video