[Case] A steel plant clean water treatment project

- date:

- browse:64

Background of the project

A steel plant is currently using a laminated filter. Because the quality of the effluent water does not meet the user's requirements, the on-site filter has been in a stagnant state. With the operation of the system, the circulating water is getting more and more dirty, causing the existing water quality to affect the rear of the circulating system. The original equipment and pipelines are seriously damaged, and the on-site equipment is frequently overhauled, and the labor maintenance cost is high. In order to reduce labor costs and extend the service life of the equipment, it is necessary to improve the on-site water quality.

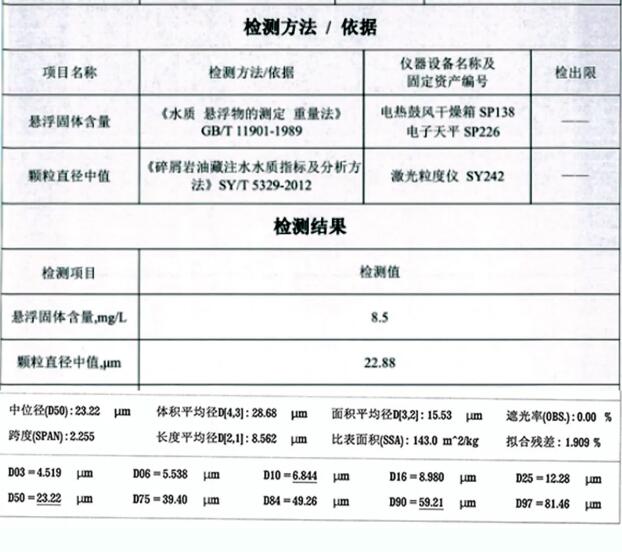

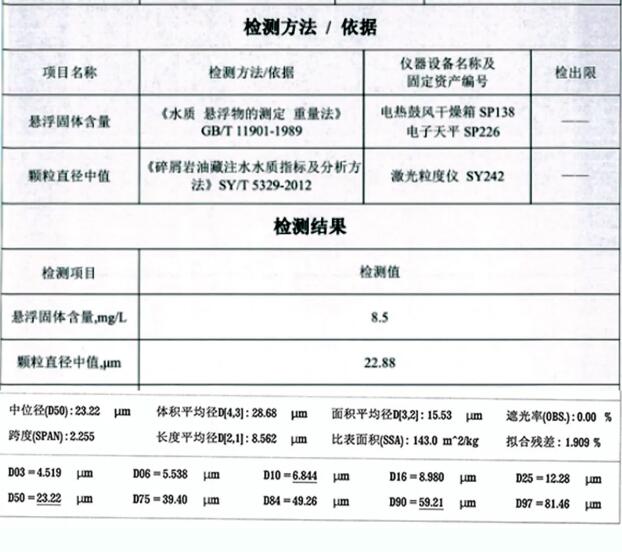

Water sample analysis

In the customer's water quality, the median particle diameter: 22.88μm, and the suspended solid content: 8.5mg/L. If the high-speed filter is selected, the suspended solids are difficult to drop. According to the test results, the multi-media filter is finally selected.

Scheme design parameters

The multi-media filter adopts multi-layer filter material, and the filtration speed is designed at 12-20m/H. The principle is that when the raw water passes through the filter material from top to bottom, the suspended matter in the water is intercepted by the surface of the filter layer due to adsorption and mechanical resistance. .

When water flows into the middle of the filter layer, because the sand particles in the filter layer are arranged more closely, the particles in the water have more chances to collide with the sand particles, so the floc, suspended matter and sand surface in the water adhere to each other, and the impurities in the water are intercepted. In the filter layer, so as to get clarified water quality.

The filtered effluent suspended solids can be below 5 mg/L.

Equipment performance advantage

Unique structure can realize online backwashing.

Backwash strength

Water: 4-12 l/s.㎡, expansion rate: 40-50%

Gas: 10-18 l/s.㎡, expansion rate: 10-15%

Backwash water inlet pressure: ≥0.15 MPa

Inlet and outlet pressure difference: 0.01-0.015MPa

Filtration Speed: 10-20m/h

Operation period: 2-7 days;

Backwashing method: water washing or air-water combined backwashing

Backwash water consumption: 1-3%

Backwash strength: 4-15L/s·m2

Backwash duration: 5-7min

Equipment delivery site

Equipment installation site

Comparison before and after filtering

Through this technical transformation, the effluent suspended solids can reach 3-5mg/L, which significantly improves the water quality on site, ensures the normal operation of production, and achieves the expected results

From planned design to construction and operation, Lifeierte has continuously improved through in-depth communication with customers time after time, and continued to develop through the refinement of the on-site program, and let customers experience Lifeierte products with practical actions. It is worthy of rest assured, the service strength is trustworthy