Introduction of SELF-CLEANING FILTER

- date:

- browse:758

- 42.228.139.250-51260

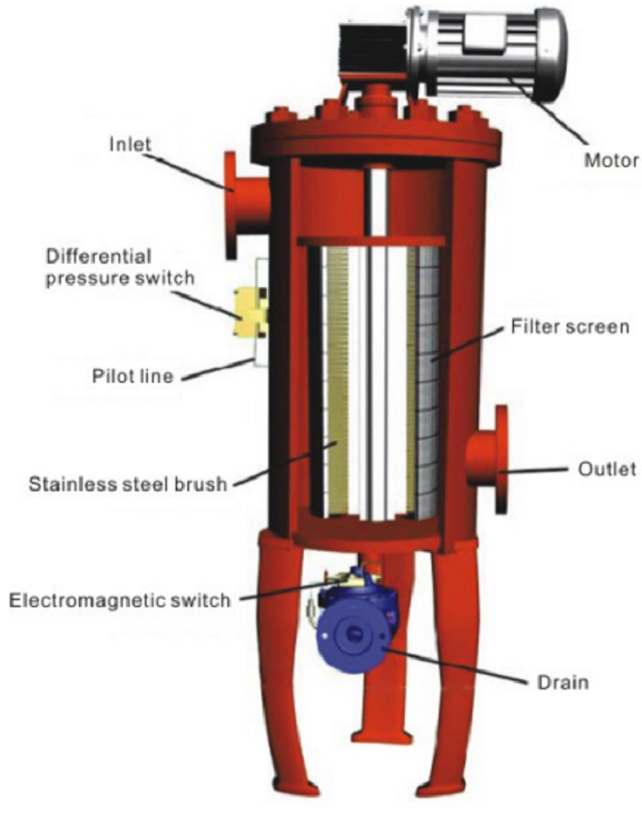

Introduction of SELF-CLEANING FILTER

Internal structure

Self cleaning filter is a kind of precision equipment that directly intercepts impurities in water, removes suspended solids and particles in water, reduces turbidity, purifies water quality, reduces system dirt, bacteria, algae and rust, so as to purify water quality and protect the normal operation of other equipment in the system. Water enters the self-cleaning filter body from the water inlet. Due to intelligent (PLC, PAC) design, The system can automatically identify the degree of impurity deposition and send a signal to the blowdown valve for automatic full blowdown. The equipment is widely used in the water treatment industry. Its simple design and good performance make the sewage achieve the best filtration effect. The main components include: motor, electric cabinet, control pipeline, main pipe assembly, filter element assembly, 316L stainless steel brush, frame assembly, transmission shaft, inlet and outlet connecting flange, etc.

Working principle

The self-cleaning filter overcomes many shortcomings of the traditional filter products, such as small pollution capacity, easy to be blocked by dirt, the filter part needs to be disassembled and cleaned, and the filter state cannot be monitored. It has the function of filtering the raw water and automatically cleaning and discharging the filter element, and the system provides uninterrupted water supply during cleaning and discharging, which can monitor the working state of the filter with a high degree of automation. It covers the requirements of various filtering accuracy from 10um to 3000um. The self-cleaning filter can automatically clean, filter and discharge without any external energy for operation and control. Continuous flow during backwashing, and the cleaning and filtration cycle can be adjusted. The self-cleaning filtration time is 10-60 / s by default, and the water loss from cleaning and filtration accounts for only 0.08-0.6% of the filtered water; The filtration accuracy can reach 10-3000 microns; The working pressure can reach 1.0-1.6mpa; Single set flow: 4-4160m ³/ h。 It can be installed vertically, horizontally and inversely in any direction and position. It can be used for water filtration in industry, agriculture, municipal power, electronics, medicine, food, printing and dyeing, construction, iron and steel, metallurgy, papermaking and other industries.

Model

1. Brush type self-cleaning filter:

The water to be treated enters the machine body from the water inlet, and the impurities in the water are deposited on the stainless steel filter screen, resulting in differential pressure. The pressure difference at the inlet and outlet is monitored through the pressure difference switch. When the pressure difference reaches the set value, the electric controller sends a signal to the hydraulic control valve and drive the motor, causing the following actions: the motor drives the brush to rotate to clean the filter element, and the control valve is opened for sewage discharge. The whole cleaning process only lasts for tens of seconds. When the cleaning is completed, close the control valve and the motor stops rotating, The system returns to its initial state and starts the next filtering process.

2. Suction self-cleaning filter

The water from the suction self-cleaning filter enters from the inlet, first filters out the impurities with large particles through the coarse filter screen, and then reaches the fine filter screen. During the filtration process, the fine filter screen gradually accumulates the dirt and impurities in the ponding to form a filter impurity layer. Since the impurity layer is accumulated on the inner side of the fine filter screen, a pressure difference is formed on the inner and outer sides of the fine filter screen. When the pressure difference of the filter reaches the preset value, the automatic cleaning process will begin. During this time, the clean water supply will flow continuously, the cleaning valve will be opened, and the water pressure in the cleaning chamber and the dirt absorber will drop significantly. Through the pressure difference between the filter cartridge and the dirt suction pipe, a suction force will be generated between the dirt suction pipe and the cleaning chamber through the suction nozzle to form a dirt suction process. At the same time, the filter electric motor drives the sewage suction pipe to spiral along the axial direction. The combination of axial movement and rotary movement of the dirt absorber completely cleans the inner surface of the whole filter screen. The whole flushing process takes only tens of seconds. The blowdown valve is closed at the end of cleaning. Prepare for the next flushing cycle from cleaning the filter.

3. Backwash self-cleaning filter

The water for backwashing the self-cleaning filter enters the filter from the water inlet. Firstly, the impurities with large particles are filtered through the coarse filter element assembly, and then reach the fine filter screen. After the impurities with small particles are filtered through the fine filter screen, the clean water is discharged from the water outlet. In the filtration process, the impurities in the inner layer of the fine filter screen gradually accumulate, and a pressure difference is formed on the inner and outer sides of it. When the pressure difference reaches the preset value, the filter will start the automatic cleaning process: the blowdown valve will be opened, and the hydraulic motor chamber and hydraulic cylinder of the main pipe assembly will release the pressure and discharge the water; The pressure in the hydraulic motor room and the sewage suction pipe decreases greatly. Due to the negative pressure, the dirt on the inner wall of the fine filter screen is absorbed through the suction nozzle, flows into the hydraulic motor room by the hydraulic motor, and is discharged by the blowdown valve to form a sewage suction process. When the water flows through the hydraulic motor of the filter, the sewage suction pipe is driven to rotate, and the sewage suction pipe is driven to move axially by the piston of the hydraulic cylinder. The inner surface of the whole filter screen is completely cleaned by the combination of axial movement and rotary movement. The whole cleaning process will last for tens of seconds. The blowdown valve is closed at the end of cleaning. The increased water pressure will return the hydraulic cylinder piston to its initial position and prepare for the next flushing cycle from cleaning the filter. During the cleaning process, the normal filtering work of the filter is uninterrupted.

Self cleaning filters are widely used to purify water. They can be used in industries, agriculture, electric power, electronics, medicine, food, printing and dyeing, construction, steel, metallurgy, papermaking, coal mines, swimming pools, landscape, greening and other fields.

If you are interested in them, please feel free to consult us!