Shallow sand filter for pig farm drinking water

- date:

- browse:183

Recent News: Our Philippine customer just ordered one set of shallow sand filter for their pig farm drinking water filtration!

Introduction:

The shallow media filtration system consists of one or more standard high-speed filtration units. It is a kind of self cleaning water filter.

The water flows through the internal water distributor and the water collector.With different media,it can effectively remove

The water flows through the internal water distributor and the water collector.With different media,it can effectively remove

particulate matter and reduce turbidity.If put in specific filter material, such as activated carbon, anthracite, etc.,the

corresponding organic matter and ions can be adsorbed and removed.

The filter unit is available in a variety of sizes from 16" (400mm) to 96" (2400mm) with different installation type.The

filter can be used as an independent filtration system,with the water pump in the existing process,if it is used as a bypass

filter,it can also be equipped with its own pump. The filter can also be installed on a common pipe with multiple processing

units.

This can achieve unlimited filtering capabilities of this system.The backwashing of the filtration system is manual,semiautomatic and fully automatic,which can be started by manual button, PLC and pressure difference.The backwash cycle

and backwash time are adjustable and are set to 3 minutes before delivery.This control is implemented by the DLFCS

automatic filter control system.Users can also choose PLC control system, which can be realized high-demand control

such as centralized or remote communication.

Advantage:

1. The core components are imported origin (BERMAD, BACCARA, SIEMEN, MITSUBISHI).

2. The filter unit adopts a single-chamber design,which has better backwashing effect and lower rate on sand leak.

3. The water collector is available in stainless steel/ABS material for a longer life.

4. The outlet pipe is set at the bottom of the unit with smaller water resistance,convenient maintenance.

Feature:

1. High filtration speed and low pressure loss,completely solve the problem of slow filtration speed and small flow of

ordinary mechanical media filter.

2.With modular settings,small footprint,less piping,low investment,the space is reduced by more than 40%, and the piping

engineering capacity is reduced by more than 50%.

3.More functions with manual,semi-automatic,fully automatic backwash operation to meet your needs.

4.The backwash water source can be selected within the system,water tower or external water source, and can be

automatically switched (special requirements).

5.It can be a single filter unit or a combination of multiple filter units,and the processing flow capacity can be expanded

arbitrarily.

6.The shell and tubes are carbon steel Q235B by phosphate surface treatment with internal and external surface anticorrosion.It can also be made of stainless steel.

Working principle:

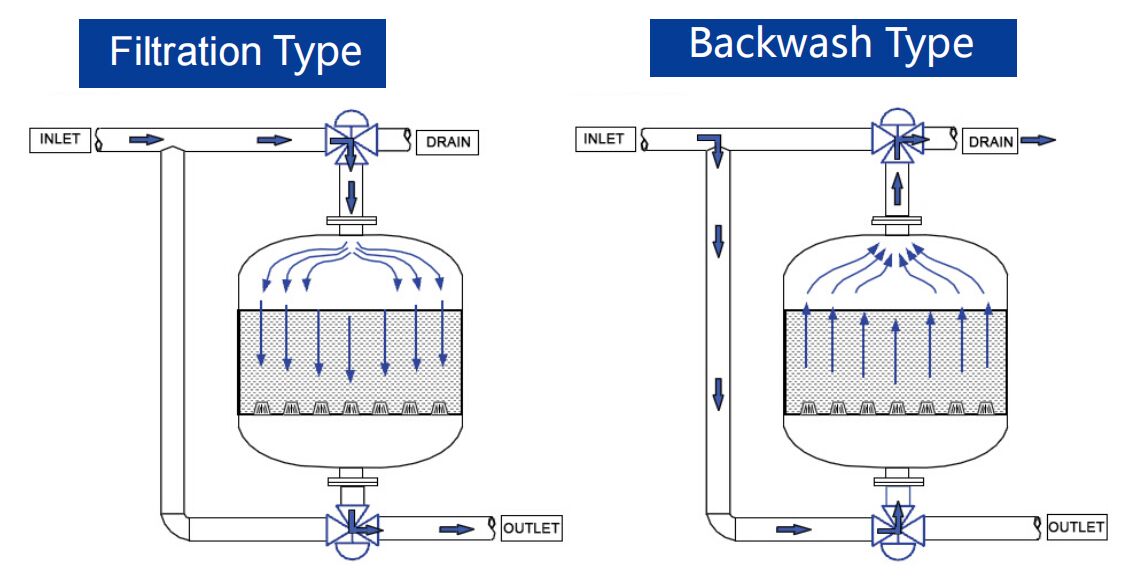

Filter status:

The unfiltered water is evenly distributed through the water distributor, and the water passes through the packing layer

in the filter in a laminar flow state. When water flows through the packing layer, impurities are trapped within the packing

layer. There are a plurality of evenly distributed water collectors at the bottom of the filter. The filtered water is evenly

collected and taken out, and the flat flow filtration can filter the filter at a high flow rate, and still achieve better filtration

effect.

Backwash status:

As the impurities accumulate in the packing layer, the internal head loss will increase. When the inlet and outlet head

loss reaches the set value or reaches the set time, the system will automatically activate the constant pressure difference

device to switch to the backwash state. When the backwash is over, the hydraulic valve changes the water supply

direction to achieve Backwashing makes it easier to clean the accumulated impurities.

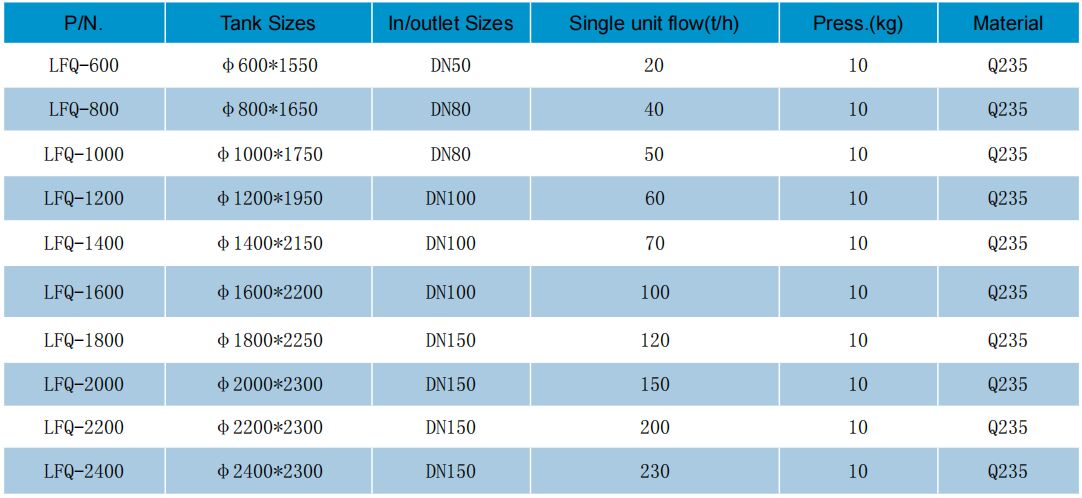

Technical data:

Application:

Last: no more news