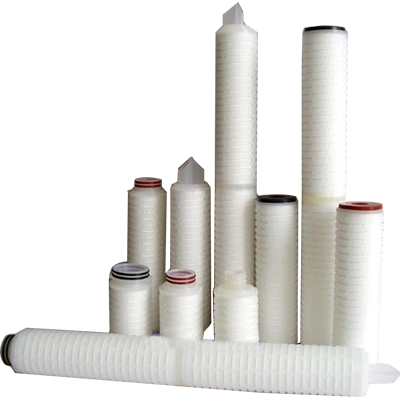

PTFE (Poly Tetra Fluoro Ethylene) Filter Cartridge

PTFE Cartridges are made up of poly tetrafluoroethylene. PTFE is characterized by high chemical inertness. These are specifically designed for sterile filtration applications of liquid, air & gas streams. They are certified, bio-safe, non-pyrogenic & fully validated to pharmaceutical standards. PTFE and polypropylene, the unique two materials used in cartridge manufacturing are chemically inert, not shedding and biologically safe according to F.D.A., USP and EEC requirements for pharmaceutical and food contact usages. PTFE cartridge membrane is used in filtering the highly corrosive solutions such as strong acids, base solution, and solvents. The membrane has about 80 – 95 % porosity & uniform pore size distribution. Moreover, the filtration area of each cartridge is as high as 0.7 m2. Therefore, it offers a high flow rate, low-pressure drop & long service life. These can be steam sterilized directly or reverse as per standardized operating data.

- PTFE membrane has excellent chemical resistance.

- End caps and connectors are sealed by thermal bond, free from binder.

- Low pressure drop and high flow rate due to high filtration area of 0.7 m2 Per 10” cartridge.

- Inherently hydrophobic expanded PTFE micro porous membrane for broad chemical compatibility & to prevent moisture obstruction in venting & wet air filtration.

- Absolute rated & precisely controlled pore size distribution for superior & constant bacterial retention.

- Autoclave or in situ steam sterilization features.

- Integrity test is possible.

- FDA approved.

| Sizes | 10”, 20”,30”,40” Long |

| Outer Diameter | 69 mm |

| Inner Diameter | 28 mm |

| Micron Rating | 0.05, 0.1, 0.2, 0.45 , 1 Micron |

| Filtration Area | More Than 0.7 m2 Per 10” cartridge |

- Double Open Type (DOE Type).

- 226 O’ Ring Design / Bayonet).

- 226 O’ Ring Design / Flat).

- 222 O’ Ring Design / Bayonet).

- 222 O’ Ring Design / Flat).

| Filter Media | 100 % PTFE (Poly Tetrafluroethylene) Membrane |

| Support Media | Polypropylene fiber |

| Inner Core | High strength polypropylene |

| Outer Core | High strength polypropylene |

| End Caps | High strength polypropylene |

| O Ring / Gaskets | EPDM / Buna N / Silicone / Viton |

| Pharmaceuticals | Electronics Industries |

| Sterilization of inlet & exhaust flow | Semi conductors |

| Vent filter | CD- R & DVD – R factory |

| Gas purification (like nitrogen & others) | Fine filtration of DI water |

| Compressed air (sterile grade) | Photoelectron chemical filtration |

| Acid / Solvents & base filtration | Wet etching process |